Due to advantages of fluidic microsystems over conventional systems (small size, flexibility, low reagent consumption, low energy consumption, speed of analysis, mobility, low cost) they are becoming increasingly employed in the field of chemistry, molecular biology, pharmacy, medicine, etc. Basic micro fluidic system is composed of micropump which pumps the liquid through the microchannels. For a good, reliable and long term performance of fluidic microsystem, design and fabrication of micropumps are usually the most challenging and critical parts. Therefore we investigated microfluidic phenomena in electromechanical-fluidic systems in order to improve reliability and performance of piezoelectric micropumps.

The suitability of micropumps for real-life application is ensured by reliable operation, long-term stability, the ability to pump two-phase medium (bubble tolerance), the ability of self-priming, low probability of cavitation, chemical stability of the materials with respect to the pumping medium and performance.

In reciprocating displacement micropumps, the cavitation is associated with high-velocity media initiated by mechanical vibrations of the membrane. To suppress cavitation, one should raise the static pressure or reduce the fluid velocity at cavitation nucleus. Raising the inlet pressure, proper priming procedure, proper geometry and relief of channels, precise valves phase sequence during operation, amplitude / frequency / wave-form of the excitation signal and fluid cooling greatly reduce the risk of cavitation. To design reliable and cavitation free piezoelectric micropumps, cavitation phenomenon was investigated in detail using numerical simulations and experiment analysis.

Operation reliability is desired quality of every microfluidic application. If the pump is not bubble tolerant, the presence of gas in the medium might result in a permanent failure of the entire system. If micropump is not self-priming, additional priming equipment and priming procedures are required which aggravate micropump start-up. Micropump bubble tolerance can be improved by increasing the compression ratio, whenever possible.

Design & numerical simulations

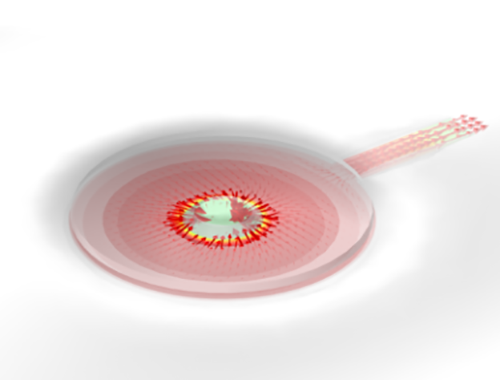

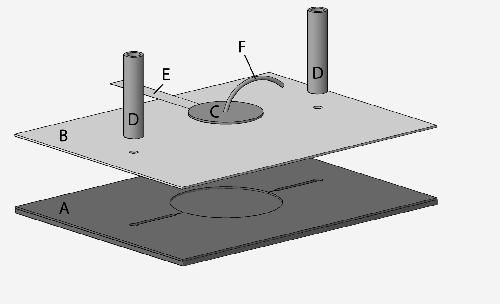

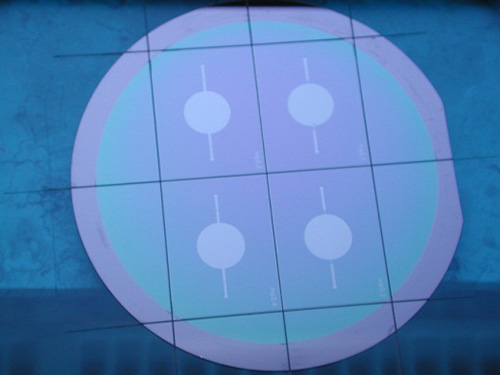

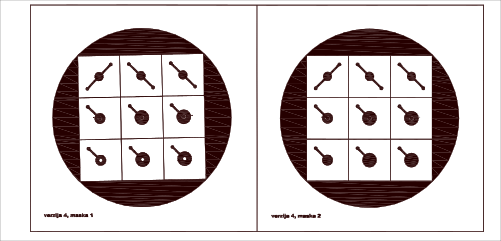

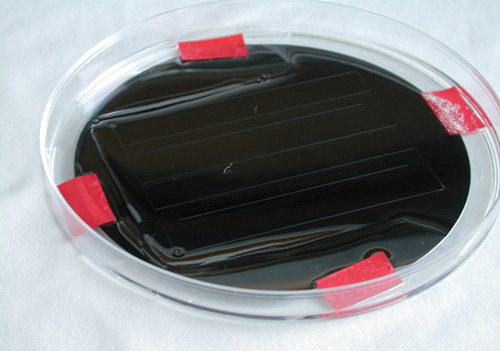

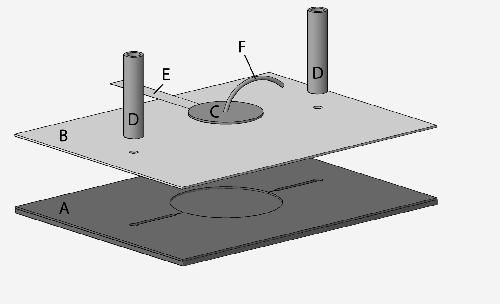

PDMS elastomer is cast using double-depth molds. See photomasks for mold fabrication on the image below:

|

| | Photolitography masks for mould fabrication |

|

|

|

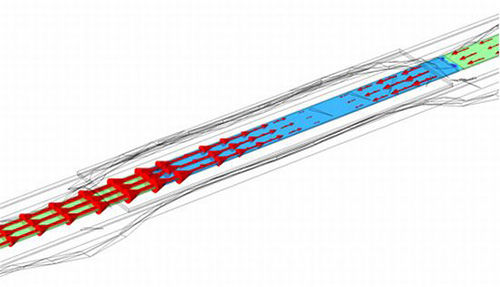

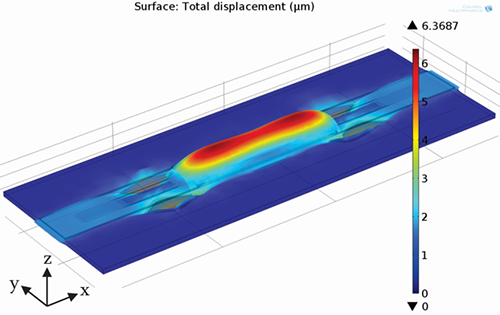

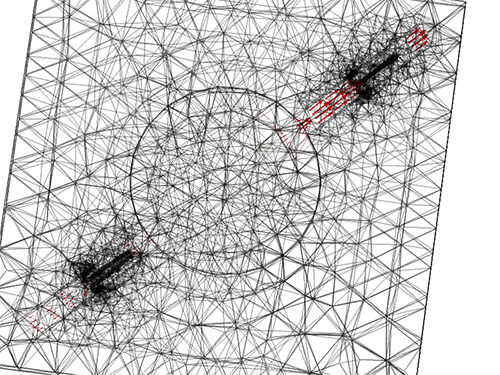

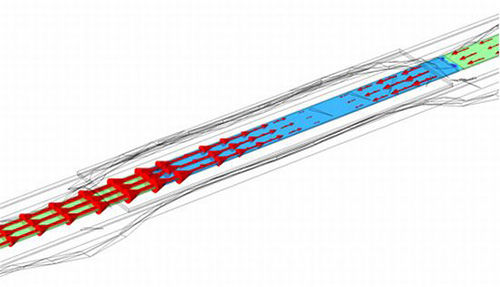

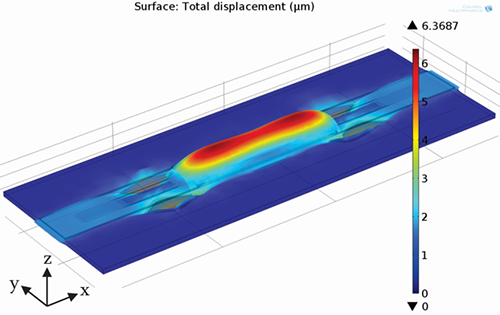

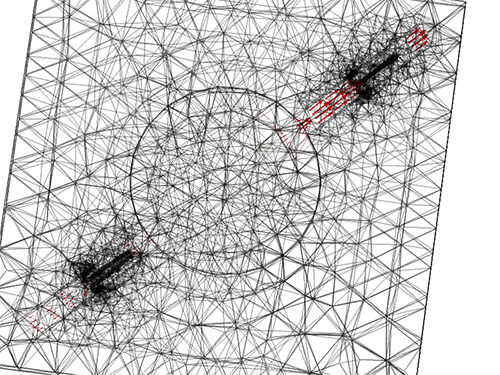

We developed a fully coupled 3D electro-fluid-solid mechanics simulation model that enables designing, numerical modeling, virtual (simulated) testing and numerical optimization of micropumps with piezoelectric actuation. Advanced simulation model covers fluid inertial effects, a hyperelastic model for PDMS and no-slip boundary condition in fluid-wall interface.

|

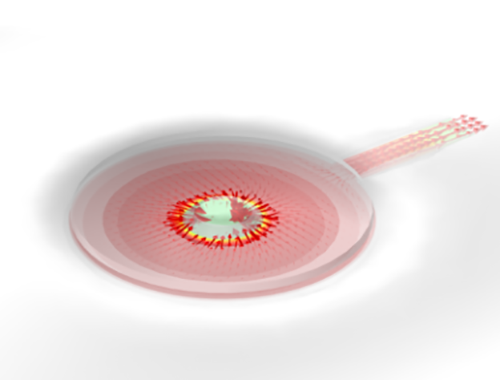

| | 3D numerical simulation: Red arrows correspond to fluid velocity |

|

|

|

|

| | 3D numerical simulation: Structural deformation of strip type mictrothrottle pump |

|

|

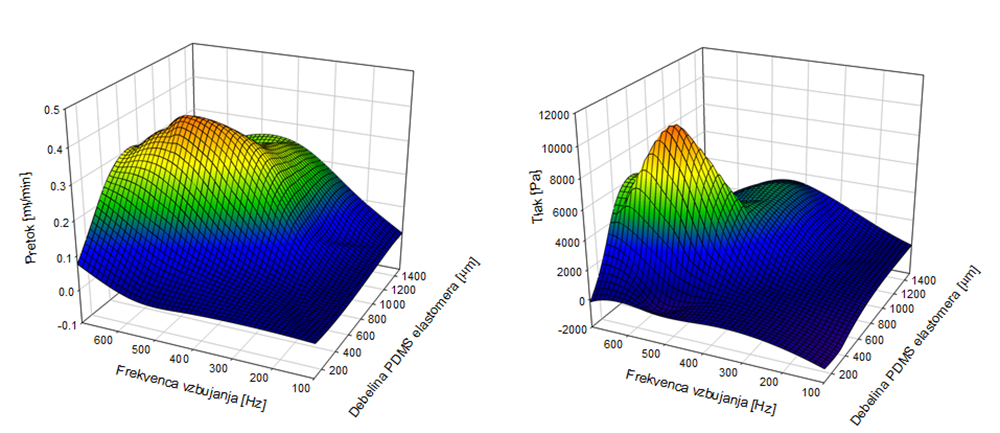

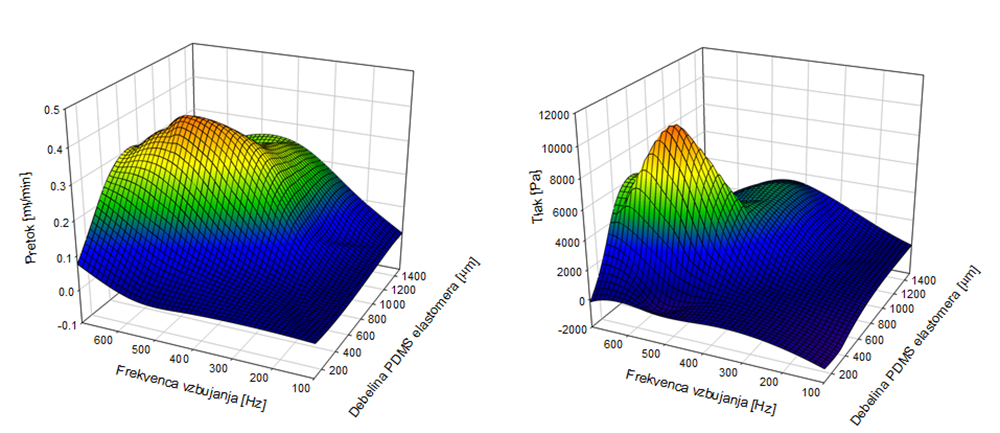

| | Numerical optimisation of cruical micropump design parameters |

|

|

| | 3-D fully coupled electro-fluidic-mechanical model of microcylinder pump |

|

|

| | 3D simulation of piezoelectric micropump which employ unique valves which mimic biologic venous valves |

|

|

|

Fabrication

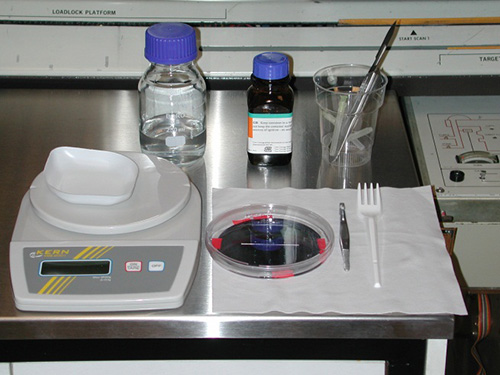

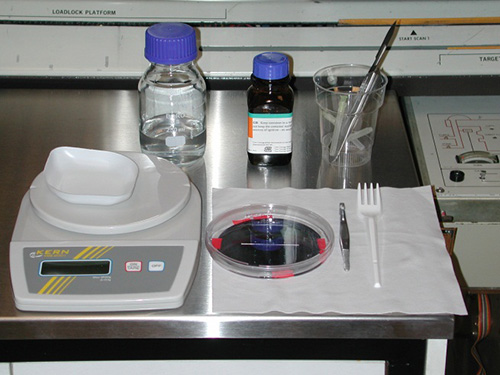

In the Laboratory of Microsensor Structures and Electronics we have developed the entire process technology for micropumps production, so that it can be cost-effective to produce even a small series of dedicated products.

|

| | PDMS elastomer is mixed with curer in exact ratio and degassed prior to use |

|

|

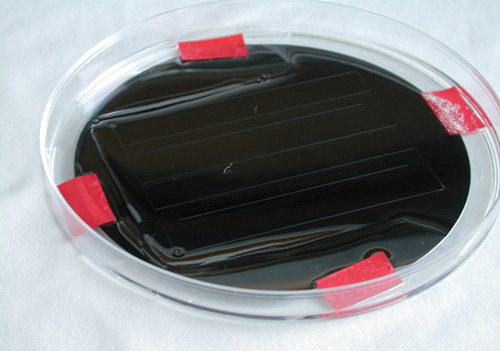

| | PDMS elastomer is poured into silicon mould |

|

|

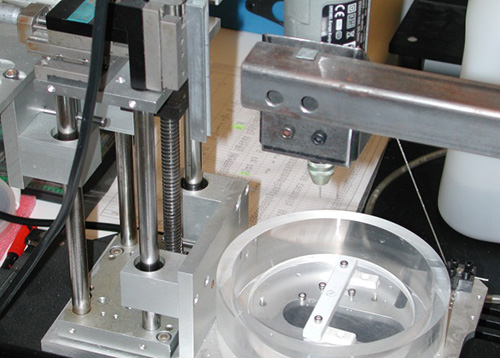

| | Micropumps can be fabricated on glass substrate which needs to be drilled to supply and drain the fluid in/out of the pump |

|

|

|

|

| Characterization

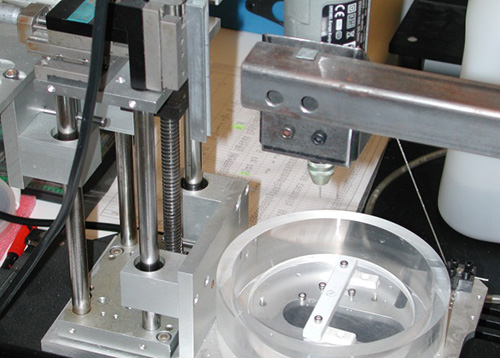

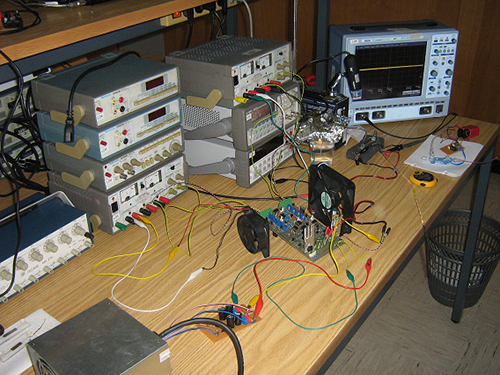

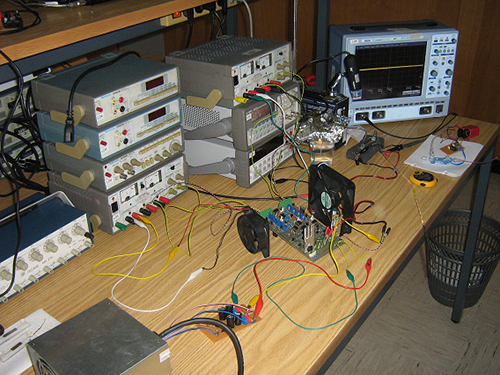

For characterization purposes, automatic characterization setup with dedicated multiple-channel micropump controller is available in LMSE.

|

| | Piezoelectric micropump prothotype characterization |

|

|

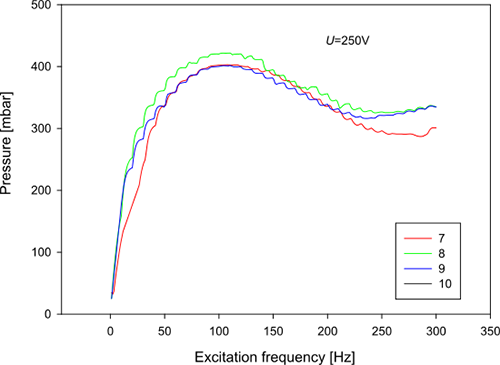

| | Characterization setup for pressure and flowrate characterization |

|

|

| | Characterization of micropump driving electronics |

|

|

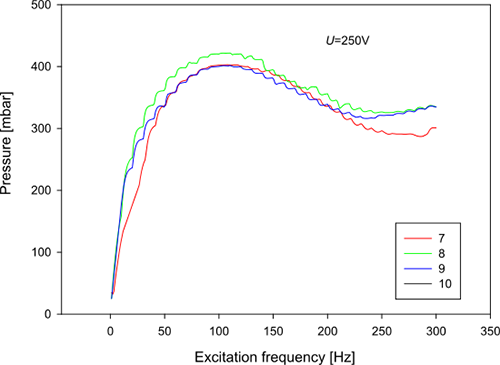

| | Microcylinder pump backpressure performance characteristics |

|

|

| Diffuser micropumps

Valves in check valves micropumps are sensitive to small particles and suffer from many problems such as wear and fatigue with long-term usage, induce difficulties such as clogging and sedimentation and have a rather complicated design. Therefore, they are not suitable for extreme miniaturization. To overcome these problems, the use of passive fixed valves as substitutes for active check valves is suggested. These pumps utilize the different pressure drop characteristics of flow through a nozzle and a diffuser to direct the flow in one preferential direction and hence cause a pumping action.

|

| | Diffuser micropumps emply nonsimetrical valve structures in the shape of diffuser |

|

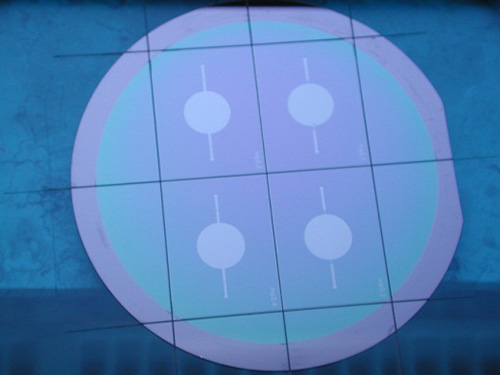

| | Silicon micropump chips waiting for anodic bonding with Pyrex glass membrane |

|

|

|

Strip type microthrottle pumps

A main challenge in development of micro pumps suitable for integration in lab-on-chip devices has been to produce a pumping mechanism that enables simultaneous and separate pumping of several liquids in parallel. Strip-type micropump with its rectangular actuator enables more efficient chip surface consumption (lab-on-chip: separate parallel pumping of media) compared to existing micropumps with circular actuators. Numerical simulation enabled virtual prototyping of the proposed device with detailed analysis of device operation at various frequencies, back-pressure, amplitude of the excitation signal as well as optimization of several design parameters such as optimal position and heights of the throttles.

|

| | Strip type microthrottle pump |

|

|

|

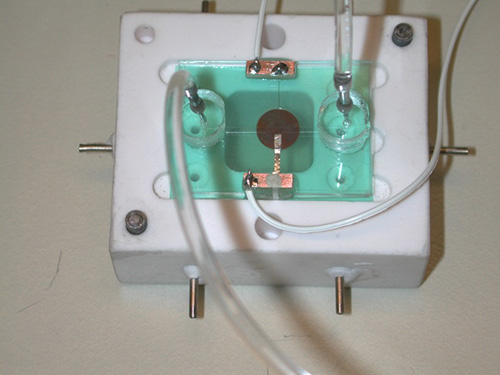

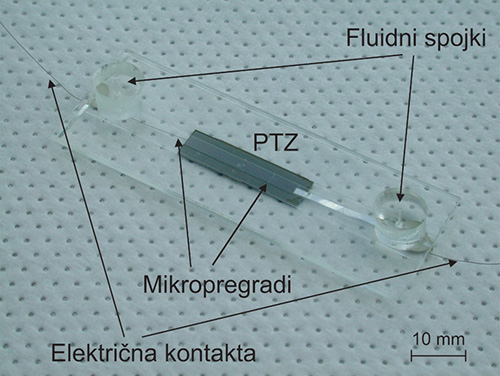

Self-priming bubble tolerant microcylinder pump

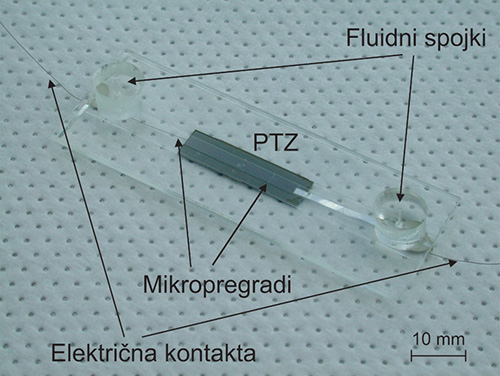

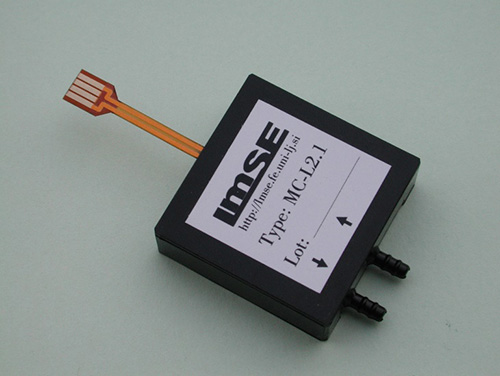

The invention relates to a new type of micropumps which have the advantage of lower cost manufacturing, increased operating reliability and better performance than competing. Micropumps specialty is their ability of non-destructive pumping of biological substances which enables effective use in biomedical applications. Micropumps could be upgraded with advanced integration of other actuator, sensor and thermo components, thereby making it possible to create dedicated applications in biotechnology, biomedicine, chemistry, pharmacy, ecology, industry and more. In the Laboratory of Microsensor Structures and Electronics we have developed the entire process technology for micropumps production, so that it can be cost-effective to produce even a small series of dedicated products. In addition, we have developed electronics which enables proper device functioning in final application. |

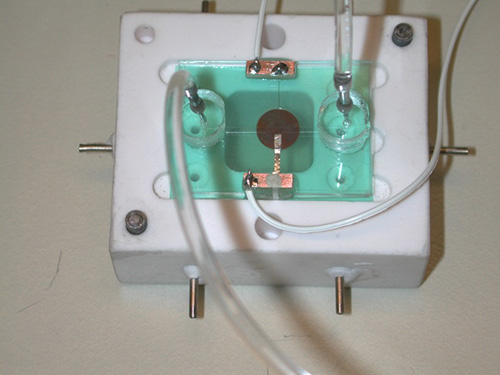

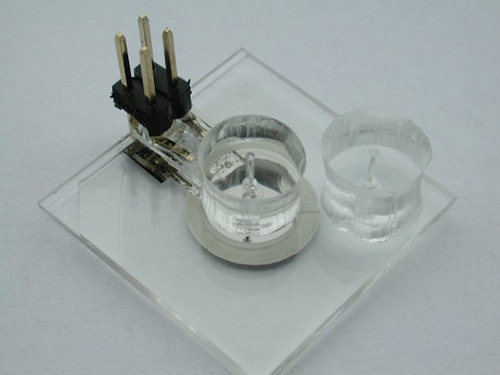

| | Piezoelectric microcylinder prothotype fabricated on glass substrate |

|

|

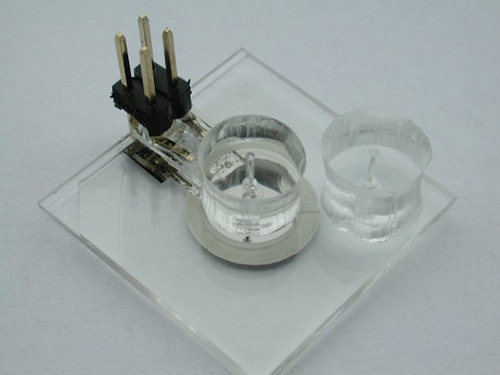

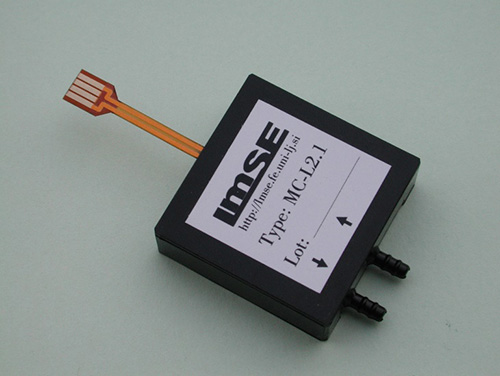

In LMSE developed microcylinder pump in professional housing (in cooperation with Kolektor group d.o.o. company)

|

| | In LMSE developed microcylinder pump in professional ABS housing |

|

|